How to Enhance Asbestos Safety in Australia's Construction Industry

Asbestos Risks in Construction

As a construction manager who often finds himself overseeing projects across Sydney, particularly those near the renowned University of Sydney engineering campus, I understand the critical importance of being aware of asbestos risks in our environment. Asbestos poses a significant safety hazard, especially when working on infrastructure developments or renovations. It's vital to identify asbestos-containing materials (ACMs) early in the project lifecycle to ensure everyone's safety.

Identifying Asbestos-Containing Materials

To begin with, understanding where asbestos might lurk in a construction site is crucial. Many older buildings, for instance, may contain asbestos in roofing materials, insulation, and even floor tiles. Engineers like Lachlan should be vigilant and proactive in identifying these areas during site assessments, as neglect can lead to asbestos exposure, increasing the risk of developing serious health conditions.

Common Sites of Exposure

Asbestos tends to hide in unexpected places. Sites prone to exposure often include areas undergoing repair, maintenance, or demolition, where structures were built before stricter regulations took effect. Think about the ceilings, walls, and even the soil surrounding old buildings. Understanding these common sites contributes to more effective control measures asbestosis compensation.

Health Risks Associated

The health implications of asbestos exposure cannot be ignored. Serious ailments such as mesothelioma, asbestosis, and lung cancer are direct results of inhaling asbestos fibers. Engaging services from mesothelioma lawyer could be one way to prepare for complex cases stemming from such exposures. Moreover, collaborating with no win no fee lawyers melbourne can ensure your team has legal support if necessary, providing a layer of security as we address these risks.

Regulatory Framework

Understanding the regulatory framework surrounding asbestos management is crucial for professionals in the construction industry. As a civil engineer operating in Australia, particularly in Sydney, it's essential to stay updated with Dandenong solicitors and expert legal advice to ensure compliance with these standards while working on infrastructure projects like those along WestConnex.

Key Australian Safety Standards

Australia has stringent regulations to control asbestos exposure, such as the Work Health and Safety (WHS) Regulations, which mandate the identification, risk assessment, and management of asbestos hazards. Failure to comply can lead to significant penalties. Familiarize yourself with the specific sections related to asbestos to protect your team and ensure that your projects align with these national standards.

Legal Compliance for Engineers

Engineers must be aware of their legal responsibilities concerning workplace safety. Obtaining guidance from experts, including some of the best no win no fee lawyers in the field, can help clarify these duties. Legal compliance extends beyond on-site efforts, it encompasses documentation and reporting procedures as well.

Recent Legislative Updates

Regulations and standards are continually evolving, demanding that you keep abreast of legislative changes. Recent updates to the WHS Regulations, for instance, may affect the way asbestos is managed on sites like those around the Anzac Bridge. Regularly reviewing official publications and attending workshops on environmental safety can prepare you for these changes. This knowledge is vital to ensure that your projects maintain safety and legal compliance.

Safety Protocols

Implementing Site Assessments

When working on projects like those along the WestConnex, it's vital to execute thorough site assessments to identify asbestos risks. Site assessments should be an integral part of any project plan, especially in areas with a history of asbestos use. These assessments typically include detailed inspections to uncover potential asbestos claims that might arise if exposure occurs due to mismanaged materials.

Training for Risk Mitigation

Ensuring comprehensive training for all team members is another critical step. Training sessions need to focus on recognizing asbestos-containing materials, understanding the procedures for safe handling, and the protocols for reporting any suspicious materials. This training is crucial not only for protecting team members' health but also for preventing potential asbestos compensation claims that can arise from workplace negligence.

Emergency Response Planning

A robust emergency response plan is essential in the unfortunate event of asbestos exposure. This plan should outline immediate actions, such as evacuating the area and notifying environmental health professionals. It should also include long-term steps like medical evaluations for those potentially exposed. Having these strategies in place can significantly reduce the risks associated with asbestos on site, providing peace of mind while working on infrastructure projects similar to the ones inspired by the University of Sydney's engineering excellence.

Implementing these safety protocols equips teams to handle potential asbestos hazards effectively, ensuring that all construction activities comply with safety standards and legal requirements.

Innovative Solutions

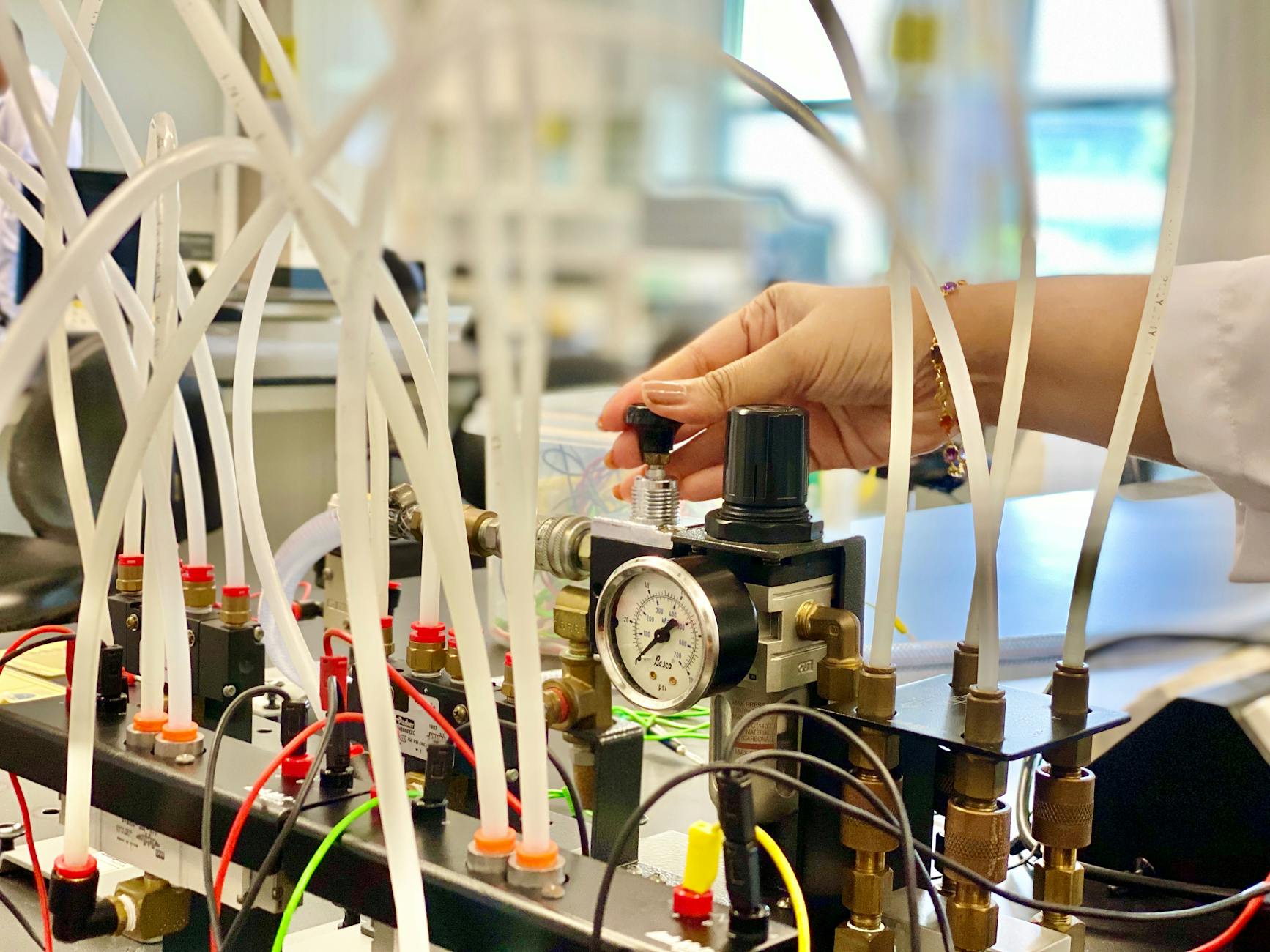

Technologies for Detection

Within the sphere of construction safety, advanced technologies are pivotal in identifying asbestos risks, a pressing concern for many professionals including transport workers class action advocates. These tools offer a proactive approach to detection, employing devices such as electronic sensors and infrared spectroscopy to precisely locate asbestos-containing materials. These technologies can significantly enhance on-site safety measures, providing an extra layer of assurance for construction managers wary of asbestos exposure's impact. Utilizing these innovations supports a diligence reminiscent of the methodologies used in major projects like those surrounding the WestConnex infrastructure expansion.

Modern Protective Equipment

Adopting the latest protective equipment can also be instrumental in safeguarding construction workers. Equipment advancements include respirators with enhanced filtration capabilities and protective clothing that repels asbestos fibers, reducing occupational exposure. The integration of these tools aligns with the standards embedded in the Anzac Bridge's structural design protocols, emphasizing workers’ safety as a fundamental priority. Being equipped with such modern gear underscores a commitment to maintaining a secure environment for all site personnel.

Case Studies of Successful Implementation

Numerous infrastructure projects in Australia have demonstrated the successful application of these innovations. On one hand, the incorporation of real-time detection technologies has proven effective in reducing asbestos-related incidents. On the other, the strategic employment of modern protective gear has yielded remarkable results in keeping workers safe. Learning from these case studies, similar to those experienced by compensation lawyers melbourne, can provide practical insights for civil engineers looking to reinforce safety protocols on their projects.

Common Mistakes

Overlooking Concealed Risks

Navigating the complexities of construction in Sydney, particularly in areas such as infrastructure projects along the WestConnex, requires a vigilant eye for potential hazards that may not be immediately visible. A common error lies in underestimating the consequences of overlooking hidden risks such as undetected asbestos fibers in older buildings. Practical insights from projects like the University of Sydney engineering campus renovations stress the vital importance of detailed inspections and continuous site monitoring. Ignorance here isn’t bliss, it’s a liability that can halt a project and endanger lives.

Inadequate Training Frequency

Regular training is not just a checkbox for compliance, it’s the backbone of workplace safety, especially when dealing with complex sites like the Anzac Bridge structural design. Far too many projects falter by not emphasizing consistent upskilling and training updates. This oversight leads to diminished awareness of ever-evolving safety protocols and can compromise your team’s ability to handle asbestos-related incidents effectively. Structured workshops and seminars focused on realistic scenarios are essential, fostering a culture of safety and proactive preparation.

Ineffective Waste Disposal Management

Missteps in managing and disposing of hazardous materials are detrimental, especially in projects embedded within urban settings. Incorrect disposal of asbestos-contaminated waste can have cascading effects, from legal actions to irreparable reputational harm. Implementing stringent protocols for waste segregation, transport, and disposal, aligned with current Australian regulations, mitigates this risk. Entire projects can benefit from using third-party auditing to ensure compliance, thus upholding the site’s safety ambitions and community trust.